This is an old revision of the document!

Table of Contents

[draft]

Words of Wisdom: “Pricing of lithium-ion batteries is slowly changing from obscenely expensive to only moderately unaffordable…” – Rob Beckers1)

Drop-in Lithium (LiFePO4)

“Drop-in” batteries are pre-built LiFePO4 (LFP) lithium (Li) batteries that are more or less the same size and voltage as lead-chemistry 12v batteries. 100Ah is the most common capacity, but larger and smaller batteries do exist.

The other approach to lithium is DIY2), where one selects cells, BMS, and other components and builds it themselves. That topic is beyond the scope of this article. People interested in DIY might want to read the DIY LiFePO4 Battery Banks subforum over on DIY Solar. You can also see the Lithium Battery Summery article for high points of a debate on lithium suitability for long term use.

Drop-in lithium benefits

- Drop-ins are ready to use. Buy it, install it.

Drop-in lithium limitations

- Drop-in batteries are typically “black boxes” with no practical way tell what is going on inside. Some do have bluetooth or other methods to interact with the insides.

- Drop-ins are not always repairable. Some, like SOK metal-cased batteries are reportedly repairable.

- Drop-ins are very expensive compared to DIY lithium

overall lithium benefits

- Li batteries (Li) have greater energy density than lead (Pb), so are smaller for a given capacity. They are also much lighter for the same capacity.

- Li batteries have very low internal resistance, meaning they can charge/discharge at up to 1C, or 100A for a 100Ah bank. Note that for longevity reasons this is often restricted to C/2, or 50A for a 100Ah battery.

- If treated properly Li can have many times the cycle life of Pb.3)

- Li batteries are not vulnerable to partial states of charge like Pb. If anything they prefer sitting at PSoC.

- flat voltage curve - stable voltage over much of its state of charge

- very little Peukert effect (reduction of capacity at higher discharge rates)

- much less voltage sag under heavy loads

overall lithium limitations

- Li is relatively expensive

- Li cells need a BMS to protect them from damage.4) For example, Li can be damaged by overvoltage, undervoltage, charging below freezing (32F), etc. Some batteries have low-temp cutoff and/or internal heating to address the cold-charging limitation. Most Drop-in Lithium batteries will have a BMS integrated into them, but raw cells do not.

- Li can be damaged by long duration at full charge or full discharge.

- the flat voltage curve makes gauging SoC by voltage extremely challenging, and battery “gauges” designed for lead chemistry batteries will not work. An amp-counting battery monitor will be more useful with Li.

charging

Note: there are many myths about charging LFP.

There are two main approaches to charging a drop-in:

- Normal - charging to manufacturer specs, which should get you through the warranty period; see charging specs below. Battle Born, for example, recommends “14.2V – 14.6V for bulk and absorption and float to be 13.6V or lower”, and absorption duration of 20 minutes.

- Advanced - charging/using more gently, which may extend life dramatically.

chargers

Some chargers are labeled “lithium-compatible”. This can mean:

- built-in configurations for LFP, which may or may not match mfg recommendations. The Renogy Rover Elite 20A, for example, defaults to 14.4v Absorption5) and stops charging6), then allows the bank to drop to 13.2v before starting absorption again.

- the charger has a configurable USER mode where you can config the setpoints you want

If you already own a fully-configurable charger then you probably don't need to buy a lithium-specific one. [my settings are here - secessus]

Note: due to the relatively low voltages of LFP banks7) while charging MPPT controllers will typically outperform PWM.

current

Lithium can famously accept huge amounts of current; this does not mean it is good for it to do so.

- Maximum8) - 1C (100A for 100Ah battery)

- Manufacturer recommendation - ≤0.5C (≤50A for 100Ah battery)

- cycle rating (longest life) - 0.2C (20A for 100Ah battery)

Lithium does not have a minimum charging current in the lead-battery sense. Charge as slow as you like.

voltage

LFP are typically fully charged at 13.6v, so Absorping at 13.8v for gentle overvolting and floating at 13.2-13.4v are common setpoints for folks who want to get maximal life from the bank. Observe cell voltages and return to mfg-spec voltage if/when balancing is needed.

Andy from Off-Grid Garage found at moderate charging rates like ~C/5:

- charging to 3.5vpc (14v for a 4S bank) at and stopping yielded near 97.6% SoC

- charging to 3.5vpc (14v for a 4S bank) and holding voltage yielded little further capacity (99.7% SoC)

- charging to 3.4vpc (13.6v for a 4S pack) and stopping yielded 89% SoC.9)

- charging to 3.4vpc (13.6v for a 4S pack) and holding voltage for 4+ hours yielded 98.2% SoC.

Why are manufacturer-recommended charging voltages so high?

Manufacturers need simple instructions that will still allow the batteries to meet their advertised lifetime and reduce customer support issues. In this scenario higher charging voltages have the following benefits to the seller:

- allow use of conventional lead-chemistry battery chargers or “lithium” chargers (reduce customer confusion)

- ensure batteries can deliver 100% of advertised capacity (reduce customer service calls)

- faster charging

- higher charging rate - bigger differences between charger and battery voltage mean more current (customer happy with fast charging). Note that more current is not necessarily the key to battery longevity.

- at higher charging voltages10) little or no absorption time is required. “Charge and stop.” (simpler for customers)

- raise cell voltage so passive top-balancing can occur (customers get to see the vaunted cell balancer feature).

an approach to greater longevity

Bottom line, stay within the manufacturer recommended specs, and you should be fine, go beyond that (more conservative) and you should be extra fine. – Dzl

[Fine vs Extra Fine is like normal driving vs hypermiling; getting big MPG numbers is possible but requires forethought and a willingness to alter one's own driving style. – secessus]

In this section we are thinking about “extra fine”. One way to baby the bank is to treat it like the manufacturer did when getting the much larger cycle numbers like 8,000. These tend to be:

- charge/discharge rates limited to C/5 (20A for a 100Ah bank)

- at human-comfortable temperatures. There is some evidence that, in addition to stopping charge at freezing, charging currents should be limited below 60F.

- not held at high states of charge (see below)

- discharged no lower than 20% State of Charge

- generally operated “between the voltage knees”

The overall idea is to treat the bank like there is no BMS, no safety net. Charging rates/voltages are conservative and charging takes longer. Note this only works if one has enough time for gentle charging; if you only have a 2-hour charging window hard-and-fast is the only option and we accept the shorter life trade-off.

charging voltage

If there is sufficient charging time, a lower charging voltage may offer these advantages:

- gentler charging rate

- less (or zero) time at 100% State of Charge

- cells more likely to stay in balance

At gentle charge rates like C/5, the following patterns emerge:

- ≤13.4v will not fully charge the bank in one day of charging

- 13.6v will charge to 100% SoC with several hours of Absorption

- 13.8v will charge to 100% SoC with a shorter Absorption and cells tend to stay in balance.

- ≥14.0v will charge to 100% SoC with no absorption. Cell voltages tend to diverge.

Some drop-in BMS only start top-balancing at 14.2v11) but increasing voltage to that level tends to cause imbalance. Catch-22.

If charging at lower votlages the initial charge (and occasional charges thereafter) might be to mfg spec voltage. This might allow the BMS to reset “full” and top-balance to the degree that such balancing works.

Also see: Will Prowse's Lithium Battery Longevity: Double or Quadruple the Life of Your Lithium Battery

myths

myth: you can charge Li as fast as you want

BMS are often configured to limit charging to 1C (100A for a 100Ah battery) as an absolute maximum. Manufacturer's who actually warranty the battery often recommend .5C (50A) or even .2C (20A) for longevity. Charging at too high a rate can cause permanent damaging to the battery.12), and the effect may be worse at low temperatures.

Charging Li at very high rates may also strain the alternator.

myth: you have to charge Li to 100%

Lead batteries require fully charging to 100% state of charge (SoC) but lithium batteries do not. Charging them fully at higher voltages can cause cells to become further out of balance. Leaving them at 100% SoC can cause degradation.13)

This paper found that charging only 50% SoC resulted in extension of

lifetime expectancy of the vehicle battery by 44–130%. When accounting for the calendar ageing as well, this proved to be a large part of the total ageing.

Having said that, there are valid reasons for charging to 100%:

- going into a period where you will need max capacity

- to perform a capacity test

- to reset the BMS amp/SoC counter

- to top-balance cells14)

myth: if you don't charge to 14.4v the cells won't balance

Charging at higher voltages (and higher rates) causes cell imbalance, which the (usually comically-undersized) balancer attempts to correct.

This occurs because the cells hit the high-voltage “knee” at slightly different times, at which point they “race” ahead of the others. Stay below the knee and the cells will tend to stay in balance on their own.

- in cyclic use (like offgrid) ~13.8v (3.45Vpc) is sufficient to reach 100% with some absorption, without antagonizing cell balance.

- when on shore power (like on a power pedestal) voltages as low as 13.4v will slowly bring the bank up to 100% SoC.

myth: you can't charge Li with a lead battery charger

Depends on the charger and how your Li wants to be charged. Most fully-configurable chargers can be used to charge Li.15) Note that some so-called “lithium compatible” chargers may have presets that do not match the requirements of your particular battery, so read the specs.

Here is the order of operations:

- Read and understand your Li battery manufacturer's charging specs16)

- Read and understand the charger's specs and functionality

- decide whether the charger can charge to mfg specs

Armed with a full understanding, here is one approach to thinking about lead battery charger setpoints:

- Absorption voltage (Vabs) - whatever charging voltage your battery manufacturer recommends.17)

- Absorption duration - whatever the battery manufacturer recommends, typically 0 to 20 minutes.18)

- Float voltage (Vfloat) - Something like 13.4v19) is a good compromise. See the discussion on float below.

- Absorption reconnect - this voltage is the setpoint below which Absorption20) is restarted. Normally in a solar configuration Vfloat is held until sun goes down, solar conditions otherwise deteriorate, or a load is applied that is more than the solar can support. Start with a value like 13.2v and see how your system behaves. Adjust as needed.

- Equalize voltage (Veq) - Li does not require equalization. If it cannot be disabled in the controller it is common to set Veq the same as Vabs so it becomes a non-issue.21)

- Equalize duration - zero, or as low as the controller will allow. Will make no practical difference when Veq is set to Vabs.

- Temperature compensation - Lead needs different charging voltages at different temperatures but Li does not. Change setting to 0mV/cell.22)

myth: you shouldn't Float lithium

Li certainly doesn't need Float voltage (Vfloat) in the sense lead-chemistry batteries do, but the Float setpoint is still useful for Li battery banks.23)

Reminder: lead requires Float because

- lead banks need to be held at 100% SoC whenever possible for their long-term health

- the self-discharge rate is so high that they lose capacity just sitting there

Neither of these is true for Li, which dislikes sitting at 100% SoC and has vanishingly-low self-discharge rates.24) So with lithium Float is used for a different purpose, as a voltage floor. It is a voltage below which the charger shouldn't let the bank fall while charging is present. Without no Vfloat (or a very low one) the bank would charge then fall until the next morning when charging starts again. After initial charging loads would run off the battery instead of the charging source. Having a sane Vfloat allows Li to “relax” after charging while retaining the desired amount of Ah/Wh capacity.

What Vfloat setpoint should actually be is a matter of some discussion and experimentation. Each setup (and use case) is different, but in general25)

- <13.4v will allow the bank to settle below 100%

- 13.4v will hold the bank near whatever SoC it was charged to. If in doubt, this is a good default for solar charging.26)

- >13.4v will continue to charge the bank beyond the SoC it was charged to during Absorption. This may be useful if the Vabs value is set intentionally low.

myth: you must use DC-DC for alternator charging Li

Depends on the battery, the alternator, the use case, and even the isolator. For example, Battle Born says this about isolator charging lithium:

Yes, you can. Under most circumstances you don't even need to modify your system.

They do recommend a BIM or DC-DC charger for banks >300Ah.

Reminder: don't idle to charge batteries. Any type of batteries.

why an isolator?

So if isolator charging might work and DC-DC charging does work27) why would we even consider using an isolator?

- you already have an isolator installed from a previous Pb bank. Might as well see if it meets needs “for free”.

- even if you have no isolator installed an isolator is much less expensive, costing as little as 1/10th the price of DC-DC. If after testing you do decide to go DC-DC you can carry the isolator as a backup.

- an isolator is likely to charge with more current than smaller (~20A) DC-DC units.

testing your isolator with Li

Here an order of operations one might use to assess whether or not isolator charging will work in a given install:

- Read and understand your Li battery manufacturer's charging specs

- Read and understand your alternator's specs

- Read and understand your isolator's specs and functionality

- observe your vehicle's chassis voltage during normal operation - note that the voltage at the battery's location will likely be lower due to long wiring and also lower when the wiring is carrying a hefty charging current

- decide whether this will work for your alternator, your isolator, and your Li battery

- install a battery monitor so you can observe current and voltage at the battery. Or use the battery's own BT access.

- make the first test run a brief one and with the Li fairly well charged.28) Start the engine and see if the charging current and voltage is acceptable. Turn off the engine.

- If that works test it with longer drives and/or with the Li at lower states of charge. Bring a passenger to observe battery monitor if needed.

Caveats:

- Only alternator charge while driving (no idling except for brief preliminary test).

- Pay attention while charging from alternator to keep from overcharging the Li or holding for long periods at high states of charge.

- You may want a manual disconnect or HVD to shut off alternator charging. These can be added on the D+ wire (ignition triggered) or electronics ground wire (VSR, solenoid, or voltage-triggered DC-DC)

but that Victron video!

Why would a manufacturer of pricey DC-DC chargers want to publish a video of an LFP pack smoking an alternator?29) And why would they turn comments off? Oh, right.

The setup:

- Victron 12v 300Ah Smart LiFePO4, no BMS. (website). ~50% DoD at the start of each test.

- Victron BMV 712 to measure current into battery

- “traditional” alternator (Expom ER-438740,30) used in small vans and passenger cars up to 2.0 liters in Eastern Europe. Quick googling this is somewhere between a 70A and 90A alternator.

- Balmar alternator (six series, with external regulator and optional temperature sensor). This dual-fan line is available in 70A, 100A, and 120A models. The 96A cap shown in the monitoring software rules out the 70A model.

The results:

- “traditional” alternator

- 3.000rpm - 78.9A. 43deg C.

- 1.500rpm - 65.1A. 43deg C.

- a 126 and 128deg C interior temps were shown but it was not clear what they they are from.

- Balmar

- 2,100rpm - 50A, 42deg C external, 74deg C internal.

- 3,600rpm - 94.3A, unstated alt case temp, 130deg C internal.

Their conclusion:31)

…issues can arise when charging lithium batteries with an alternator.

Duh. Especially when charging a 300Ah no-BMS bank from a ≤90A alternator at idle.

They go on to list the workarounds:

- install a high output alternator that can handle demand at idle ($hundreds)

- fit an externally-regulated alternator with temp sensor, as shown in the video (~$850)

- or (surprise!), install a Victron Orion Tr-Smart DC-DC charger (~$250)

- {not mentioned: adding resistance with a shunt32) (~$34).

I would very much like to have seen the regular alt and all three four workarounds demonstrated at the same RPM settings.

further reading

- mega-thread on DIYsolarforum, including using a resistor to decrease current.

myth: floating will cause microcycling

Microcyling means bouncing between two33) voltage setpoints. The concern here is that each one of these bounces would count as a cycle and subtract from the rated 3,000 cycles or whatever the manufacturer claims. Those who take this position suggest setting Float voltage to the same as Absorption voltage to avoid microcycling. The drawback to this approach is two-fold:

- Li doesn't like to be held at 100% State of Charge for long periods

- In practice a solar-charged bank doesn't bounce between Float and Absorption during the course of a day

The 2nd point takes a bit of explaining. A solar charge controller completes Absorption then falls to into Float where it will remain as long as the sun34) cooperates. Absorption can be re-triggered if voltage falls below the Absorption Reconnect setpoint, but that setpoint is even lower than Vfloat. If that happens the solar charging has already been overtasked and we will get a “microcycle” during that day in any case if the sun comes back.

myth: lithium doesn't lose capacity under heavy loads

Lead batteries famously yield different capacities at different discharge rates; this is the reason they are rated at a specific rate (C/20).

Lithium batteries do exhibit lower apparent capacity under extreme loads35) but the mechanism is concentration polarization rather than Peukert.36) At normal discharge rates (<1C) LFP capacity is relatively stable.

BMS functions

Lithium cells can hurt themselves if left unsupervised. A BMS (Battery Management System) is device that tries to keep them out of trouble. It's like a fence around the yard that won't prevent skinned knees but should keep the kids out of the street where they could get really hurt.

Drop-in Lithium batteries all have a BMS integrated inside of them, so there is typically less to worry about. However, not all of them will have the same protection features so do your research carefully.

Typical BMS protections may include:

Charging cut-off

Charging is disabled for a few different reasons: temperature extremes, high cell voltage, overcurrent.

People who camp in cold weather may want to select a battery that has “low temperature cut-off”, which disables charging near freezing.37). The belt-and-suspenders solution is both low temperature cutoff and a way to keep the batteries warm. Some pricier batteries have internal heating, or you may DIY a heater.

Note that the BMS overcurrent protection kicks in only at the limit, typically 1C (100A for a 100Ah battery). See the section on the benefits of even gentler charging.

discharge cut-off

Discharge is disabled for similar reasons as charging: extremes in temperature, cell voltage, or current.

The low temperature discharge cut-off is typically much lower (like -20C) than for charging.

cell balancing

Cell balancing attempts to keep all the cells in the same voltage ballpark. The method used in most drop-ins is passive balancing, which applies a small amount of braking a bit on runaway cells.38)

Cell balancing attempts to keep all the cells in the same voltage ballpark. The method used in most drop-ins is passive balancing, which applies a small amount of braking a bit on runaway cells.38)

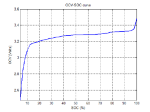

The image on the right shows the LFP voltage curve: a lower knee (below ~3.2v) on the left, a wide, flat section in the middle, then the upper knee (~3.4v) on the right. Between the knees the voltage stays relatively flat and cells stay in relative balance. The first cell[s] that hits a knee will race in that direction ahead of the others.

This matters because voltage extremes, high or low, are not good for the cell. Cell imbalance can change effective capacity, since a wayward cell could trigger cell voltage BMS protection before the bank is fully charged or discharged.

Consider these two batteries, using made up round numbers to illustrate the point. Cells are arranged in series so the volts add up:

- balanced39)

- overall battery voltage = 13.6v

- cell 1 = 3.400v

- cell 2 = 3.400v

- cell 3 = 3.400v

- cell 4 = 3.400v

- unbalanced40)

- overall battery voltage = 13.6v

- cell 1 = 3.300v

- cell 2 = 3.400v

- cell 3 = 3.400v

- cell 4 = 3.500v ←- balancer will try to slow this one down

In both cases the overall battery voltage is 13.6v, but in the unbalanced battery cell #1 is lagging (reducing capacity) and cell #4 is too high. The balancer will attempt to rein in #4 but the effect is tiny. Using a typical balancing current of 50mA, if you are charging at 20A that means the cells are receiving 5A except cell #4 which gets only 4.95A, about a 1% difference. Tiny balancing currents and the propensity of cells to race away explains why balancing is so gradual.

minimizing cell imbalance

It is more practical to minimize imbalance than to try to rebalance them after the fact. Here are some approaches:

- discharging gently, maybe a max of C/2

- charging gently (minimum current needed to get the battery charged in the amount of time available). 50mA only makes a 1% difference when charging at 20A but 4% difference at 5A.

- charging voltages closer to 13.6v than to 14.4v.41).

- charging to a lower SoC, like 85%-95% instead of 100%.

bluetooth

Some batteries have BMS with bluetooth or other forms of connectivity. With these you would be able to see more information, like individual cell balance, statistics, setting and the status of any protections.

Brands and specs

The most popular drop-ins at various price points appear to be:

- premium - Battle Born

- moderate - SOK

- inexpensive - Chins (no cutoff) or Weize (cold cutoff)

Charge/discharge rates are expressed in C. Heated models typically shunt charging current to the internal warmer until the battery comes up to safe temp.42)

[Please verify stats and specs before ordering. This is a best-effort listing but things change fast in this segment - secessus]

Battle Born

With cold cutoff. BB also has a line of heated LFP.

Will Prowse teardown video. Absorption 14.4v for 20 minutes, Float 13.6v. Recommended charge rate C/2.43)

Victron

These batteries have cold cutoff. The batteries themselves do not have bluetooth, but are intended to be connected to other Victron gear that can talk to the batteries. Victron's value proposition is increased inter-device communication when installing a Victron ecosystem.

Charge 14.2v @ C/2, Float 13.6v.44)

SOK

SOK models are popular with tinkerers because the case and internals are easy to disassemble for service, inspection, and troubleshooting.45)

With cold cutoff. Will Prowse teardown video

Charge 14.6v, max 50A, 20A recommended.46),47)

Rebel Batteries

Rebel Batteries - with cold cutoff and bluetooth (BT demo). Will Prowse teardown video

RB says “just make sure [the charger] has a Lithium charging profile”.48) The shore power charger they recommend charges at 14.3-14.4v @ 20A. The BMS has a max charging rate of 100A.

- 100ah 12v - BMS appears to be JBD SP04S028

Weize

Cold cutoff. Will Prowse teardown video

- 100Ah 12v (not currently listed on Amazon)

Ampere Time

Renogy

Renogy's original “Smart Lithium” line has no cold cutoff. They are releasing a new line of temp-protected, bluetooth enabled batteries.

Charge 14.4v @ max C/2.50)

Relion

Unheated versions appear to lack cold cutoff. No bluetooth.

Charge 14v - 14.6v, 1C up to 100A max. Float 13.3v - 13.8v.51)

Kilovault

Kilovault HLX series, internally heated. Recommended by Marine How-To.

Lithionics

- Lithioncs GV125, also recommended by Marine How-To.

Chins

Base models with no cutoff or bluetooth and “Smart” models with 5A internal heating and bluetooth (BT demo).

Will Prowse teardown video of base model; he notes they are similar inside to Ampere Time.

Absorption 14.2-14.6v, C/5 charging recommended, C/1 max.52) Heating element on supported models appears to turn on near freezing then turn off at 50F.

- 100Ah heated (Will's YT teardown)

There have been reports that the BMS does not disconnect the battery at low voltages. External LVD is always advisable.

batteries with troubling reports

further reading

- Marine How-two arcticle on drop-ins. ←- highly recommended

- Overkill Solar BMS manual (pdf).

- Battle Born: Can I charge my batteries using the alternator? (yt)