Table of Contents

Alternator details

Also see the alternator charging overview article.

theory of operation

An oversimplified overview will help us understand the challenges and approaches to overcoming them.

- An alternator makes alternating current (“AC”, hence alternator) by rotating an electromagnetic - field through stationary wires (“windings”)

- the AC is turned into direct current (“DC”) when passing through “rectifying” diodes

- voltage output is controlled by current production

- current production is controlled by varying the field current energizing the electromagnetic field

All vehicles monitor(“sense”) output voltage and adjust alternator output to maintain that voltage. Modern vehicles often monitor alternator heat and limit current to prevent damage. Older vehicles may not.

Setups with external requlators (see below) can carefully control alternator output to achieve specific results.

Many of the lessons learned about bank charging by alternator have been learned from people who live on boats. Most of their power is generated from the alternators while they “cruise” at slow speeds throughout the day. Their use case is extreme:

On boats alternators are low RPM, in an enclosed space with bad airflow, charging huge batteries and large loads1)

the challenges

Our banks will see two things when charged from alternator: voltage and current. Bot need to be appropriate for the chassis and the house bank.

Producing power makes heat as a by-product. Excess heat can destroy the alternator. How do we balance the bank's thirst for current while protecting the alternator from itself?

voltage

Alternator voltage output is intimately related to current. In the simplest model the alternator's voltage is controlled2) by a voltage regulator. The regulator uses current to hit the desired voltage setpoint.

- vehicle voltage stable at 14.0v (for example)

- loads are added, causing system voltage to drop to 13.7v

- regulator tells alternator to make more current, causing voltage to stabilize at 14.0v

- loads are removed, causing system voltage to rise to 14.2v

- regulator tells alternator to make less current, causing voltage to stabilize at 14.0v

[the alternator] has no way of knowing how great the load is. It only cares about the voltage at the regulator terminals. if it is below the set point, it will produce all of the power it possibly can at the given RPM's. If it is at the set point, it will reduce the power generated to the level that will not overshoot the set point voltage. The battery is what is supplying the power to the load and the alternator is trying to keep it at the set point voltage. – hwse

Note: Smart3) alternators do not have a firm voltage setpoint; they vary the voltage target based on conditions. This is intended to improve overall MPG. Voltage might plummet during full acceleration (to free up engine power) then spike quite high in other conditions. This wide variance complicates bank charging, and typically means a DC-DC charger is required.

regulation

Most alternators have been internally-regulated – the voltage regulator is built into the alternator case itself.

Externally-regulated alternators are alternators where the regulation function is physically separated from the alternator. There may be a stand-alone external regulator or the engine ECU may assume those duties.

see External Regulation below

tricking the regulator

Since the alternator only knows what voltage it is receiving at the regulator, an alternator can be tricked into adjusting output voltage by:

- sensing voltage at somewhere other than the starter battery4)

- placing something inline with the sense wire that changes the voltage. This might be done to increase charging voltage in order to increase current, or might be to compensate for voltage drop through a diode-based isolator. Be careful to keep alternator output voltage in a range acceptable to the vehicle itself.

current

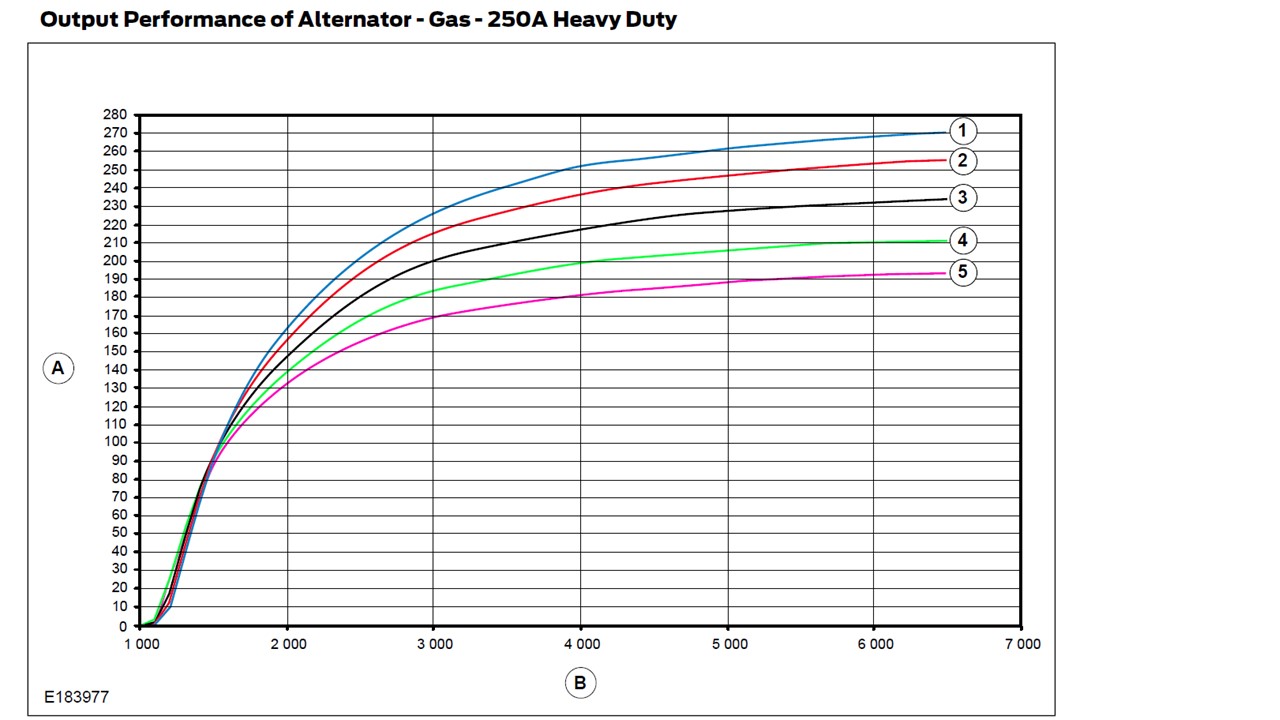

The specs for your alternator will include an amp (A) rating. This might be 80A for a passenger car, 150A for a cargo van, or >200A for a heavy duty vehicle. You can often find the actual rated output of your alternator in your manual, vehicle specs, or using a VIN lookup tool for your brand of car.

This rating is a measure of how much electrical current it can make under optimal conditions, typically:

- while the alternator is cold;5) and

- being spun at an appropriate RPM

These conditions are not often present in normal use. For this reason a continuous duty rating (CDR hereafter) is more helpful for assessing how hard we can push the alternator. In the absence of a stated CDR we can assume CDR is roughly 50% of the alternator's output rating.6) The continuous duty rating is the limiting factor when charging house batteries or running other long-duration loads. Note that the CDR does not represent how much power is available for house battery charging; the vehicle still has to run its own loads like ECU, lights, fans, etc.

For the purposes of this discussion we will assume a cargo van with an alternator rated 140A.

how many amps can I pull from the alternator?

Alternator output in the short term and longer term is affected by several factors

Alternator output in the short term and longer term is affected by several factors

- the rating above

- heat, which is the destroyer of alternators

In the absence of further information one might use some crude rules of thumb:

- at idle discretionary loads ≤25% of rated output.9). For our 140A alternator this would be 35A. Note: this is about stopping at red lights or in traffic; idling the engine to charge batteries is not recommended.

- while driving loads ≤33% (66% of CDR) For our 140A alternator this would be 47A.

- if alternator output voltage drops below normal, the belt starts to squeal or engine RPM is affected the alternator is overloaded and loads should be reduced or charging disabled.

One could make a more informed decision this way

- acquire the output chart for your alternator

- use a clamp meter to see what current the chassis draws with blower on, lights on, etc at a given engine rpm

- do the math: [output rating at that rpm / 2] to get continuous output rating at that rpm. Subtract chassis loads. The remainder is what you have left over to use.

The optimal arrangement is a temp-sensing external regulator that runs the alternator at maximum safe output when required and lower output when temps get too high.

A poor man's version of the temp-sensing regulator involves epoxying a thermistor to the alternator housing. This turns off the charger/relay at a given temperature.

In some scenarios output might be limited by placing a resistor in series with the alternator's field control wire.

If one is completely stumped:

- default to the smallest DC-DC available, typically 15A-20A

- avoid idling the van to charge

effect of alternator charging method on current

The various charging methods have different costs, some have different install locations10), levels of voltage/current control, etc.

Example: since charging voltage is a fundamental part of the current formula I=V/R we can have different charging currents, all other things being equal. Let's assume a battery bank at 12.1v, alternator at 14.2, total circuit resistance of 40mR, and a DC-DC configured to charge at 14.4v:

- relay - (14.2-12.10) / 40mR = 53A

- diode-based isolator - (13.5-12.10) / 40mR = 35A

- DC-DC - (14.4v - 12.10) / 40mR = 58A

heat

Heat in the alternator comes from

- the engine block (radiation and conduction)

- the radiator (radiation)

- ambient temperatures

- the alternator itself - alternators are most efficient (produced the least heat per watt) at normal vehicle cruising speeds. At low RPM and high RPM more heat will be generated:

- bearing heat (increased friction from failure, misalignment, overly-tight belt, etc)

- the coils

Cooling comes from:

- alternator fans, typically two attached to the rotor inside the case, but some have external fans. These fans do not move sufficient air at idle RPM.

- ambient airflow (breezes, forward motion, external fans). When the vehicle is not moving airflow under the hood is greatly decreased.

- case surface area, so large-case alts tend to run cooler13)

- current reductions, if temperature-sensing regulation is present

- moving hot items outside the case (see rectifying diodes above)

If you want the alternator to run cool rip out the internal rectifier and build an external rectifier… Otherwise fit large frame alt and run it at a current limited output. Maine Sail14)

heat-related failure modes

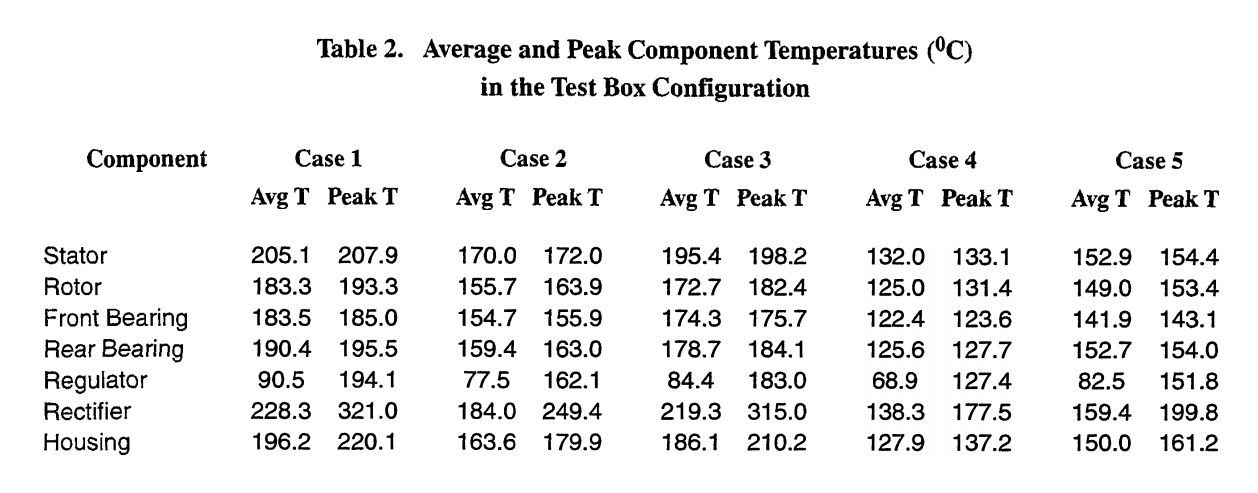

Alternator heat is typically measured on the case, although internal parts will be hotter.

Temp sensor should be measuring as close to the stator as possible15)

A common rule of thumb for a safe upper limit on case temps is 100C/212F16), although more conservative temperatures might be advisable.

Critical internals will be hotter than the case itself. For example, during the infamous Victron video both internal and external temps were given for the Balmar setup making 50A @ 2,100rpm. The case was 42C (108F) while the internals were 74C (165F). This alt was on a bench rather than mounted to a hot engine block. See table at right for examples of external/internal temps observed during lab testing.17)

Critical internals will be hotter than the case itself. For example, during the infamous Victron video both internal and external temps were given for the Balmar setup making 50A @ 2,100rpm. The case was 42C (108F) while the internals were 74C (165F). This alt was on a bench rather than mounted to a hot engine block. See table at right for examples of external/internal temps observed during lab testing.17)

- the varnish insulation on the windings will be degrading by 155C (310F)

- if temperature compensation is present it may begin around 255-260F.20) The quote above about using 120C may be a designed to cut alternator charging just before the ECU/regulator kicks in.

thermal switches

In a comment on an excellent video about charging lithium from the alternator WorkingOnExploring talks about adding overtemp protection with a thermal switch (a small bimetallic switch):21)

a KSD9700 120C, normally closed thermal switch epoxied to your alternator case. That way, if some abnormal event occurred and the alternator overheated, it could deactivate the [combiner] till the alternator cooled. It would likely cost less than $20 to install this thermal safety.

The idea here is to run the relay's control circuit22) through the Normally-Closed23) thermal switch. When the switch hits the defined temperature the circuit opens24) and power to the combiner is cut off; house bank charging from the alternator is stopped. The switch will typically reset when temperature drops by ~25%; read the datasheet for your switch for specific details.

If one had a DC with a current-limiting function (renogy's 20-40-60A models, for example) or DC-DC in parallel one could use two different-spec switches to achieve staged charging. Using placeholder temps:

- run an aggressive charging setup full blast

- at 90C engage current limiting

- at 120C disable charging completely

Note: 120C = 248F. Other temps like 90C (194F) and 100C (212C) are available and may be gentler on the alternator. Because the alternator is mounted to the block the alternator case may be at the ~same temp as the block. Check case temps when engine has been running to get a feel for how hot the case should be, preferably at the location the diodes are heat-sinked to the alternator case.25)

manual switches

It is often possible to disable alternator charging when ambient heat, traffic jams, or other factors conspire to overheat the alternator.

known temperature configurations

idling to charge house batteries

Idling the engine to charge house batteries is a perfect storm of underperformance

- the alternator is spinning too slowly to make the CDR

and heat

- the alternator is spinning too slowly for internal cooling fans to work well

- the alternator is producing more heat than power due to inefficiency

- there is no airflow from forward movement to directly cool the alternator…

- … or to remove superheated air under the hood

The situation is bad enough with relays, but even worse worse with DC-DC because

- they tend to hold full output for hours on end rather than tapering

- when the alternator struggles and voltage drops the DC-DC will demand more current to make its output target. Hopefully the charger has a minimum chassis voltage for operation and will not drag the chassis down excessively

anecdote

We have 500ah of lithium that can be charged at 3C, a theoretical 1,500 ampere charge rate. We have the Nations 280 amp second alternator. We control the Nations alternator with a DIY regulator that allows us to pretty much set the charge level anywhere we please. We'd be pleased to set it to 200+ amps, but that turns out to be impractical. The reality is, if we set the charge rate to 125 amperes, we cannot continuously charge at this rate while standing still unless the outside air temperature is 55 degrees or below. When driving at highway speeds (which cools the alternator), we can run a continuous 150 ampere charge rate at virtually any outside air temperature. While we have not tested this further, we suspect that should we desire to 'up the ante' much beyond our current 150 (sometimes 175) amperes, we would again find ourselves temperature limited even while driving. - winston

load dumps

The alternator's voltage regulator responds to demand, increasing and decreasing field strength (and therefore output) as required to hold a given voltage setpoint.

- when loads are added chassis voltage will drop briefly while the regulator responds.

- when loads are removed chassis voltage will spike briefly while the regulator responds.

- if large loads disappear suddenly and nothing is available to absorb the spike that excess voltage can damage the alternator and/or other electrics.

In typical installs there are places for the power in the alternator to go, chiefly the lead starter battery:

The real problem is secondary alternators dedicated to LFP charging; if the BMS disconnects charging there is no starter battery on that separate circuit to absorb the energy.

For a typical install the question is: how much charging current are we talking about, and does the alternator already handle that level of sudden disconnect under normal operation? Secessus provides this example:

In addition, the speed of the disconnect plays a part:

there is a massive difference in the voltage spike from a 5 uS relay disconnect and a 10mS mosfet disconnect [as found in the BMS]36)

When an alternator is outputting Big Power and the demand for that power vanishes the alternator (and other chassis electricals) can be damaged:

When the rotor current is stoked up to create a large rotor magnetic field for high alternator output and there is a sudden drop off in alternator load, the stored rotor energy takes some time to dissipate. This causes a voltage spike in output of the alternator if there is suddenly little to no load on alternator… the voltage spike can be up to several hundred volts when loading suddenly drops off. This can damage alternator diodes by exceeding their maximum voltage breakdown rating as well as any electronic equipment powered on the alternator output DC bus.37)

approaches

- use the lead starter batt in the circuit to absorb the spike

- charge the bank in a manner unlikely to cause BMS disconnect in the first place

- for LFP-dedicated alternator setups

- consider a system that uses CANBUS or other networking protocol to inform the alternator's regulator prior to actual BMS shutdown. The alt shuts down before the BMS so there are no spikes.

- install a possibly-sacrificial protection device. They are typically mounted between the alernator's B+ and B- terminals and short to ground when voltage spikes above a certain level.

- The Balmar APM-12 apparently uses “A TVS (avalanche diode), Littlefuse brand, unipolar, 15kW peak pulse capability, with a stand-off voltage around 20 or 22 Volts”38)

- the Balmar TSP-12 spike protector may be the equivalent of the APM-12 without the LED and audio indicators.

- Sterling APD12 internals not documented

- mikecol recommends a “IN6277A TVS diode in series with 5A ATC fuse. The fuse characteristics with the diode clamp makes the full circuit. I don't have data to show it works well, but worth the cheap cost for me. Fuse and diode might not survive after hit, so good to be able to check condition (I have fuse end to alt+ so can measure with voltmeter [easily]”41)

common modifications

external regulation

External regulation can provide overtemperature protection (see section on Heat above), current limiting, and can also cause the alternator to behave like a smart charger with multistage charging.

In a camper/RV context an externally-regulated alternator typically means an aftermarket external regulator controlling a dedicated secondary alternator.42) Depending on the implementation external regulation might provide:

- configurable current levels and/or voltage setpoints

- temperature monitoring so maximal current can be extracted without overheating

- RPM-based output limits

- slowly ramping up current to avoid belt slippage/damage

- shutoff when commanded by BMS

- CANBUS and other communication

- etc

External regulators include:

- Balmar ARS-5 (no external voltage sensing)

- Balmar MC-614 (external voltage sensing)

- Xantrex Xar (no external voltage sensing)

- Wakespeed WS500 (CANBUS)

- Arco Zeus - new to market

- Mastervolt, more often seen in marine installs

P-type vs N-type regulation

The alternator is controlled by varying the signal on the field control wire. The strength of the electromagnetic field drives current, which drives system voltage.

The field control wire can be on the Positive43) or Negative44) side of the field control circuit. Most internally-regulated OEM alternators are P-type with the regulation occurring on the positive side.

Balmar only builds P-type regulators because:

With an N-Type design, if the field wire shorts to ground, or if the alternator internally shorts to ground, the alternator will immediately produce full output… with… P-Type regulation… if the field wire shorts to ground or the alternator develops an internal short, the included fuse on the field wire simply blows and the alternator stops all output… When converting these units to be used with a Balmar external regulator, the alternator must also converted to P-Type for safety and compatibility with our regulators

Wakespeed apparently regulates on the P side but offers a N-type harness:

The vast majority of the time, a P-type harness will work — although there are some regions like Europe, where externally regulated N-type alternators are more commonplace. In most situations where an alternator is being modified to support external regulation, the technician making the modification has the option to set up the alternator for P-type regulation. This is by far the most commonly chosen field excitation route. Just about all of the aftermarket externally regulated alternators available in the U.S. will be configured to be excited on the positive brush. If you are not familiar with the modification process, we do recommend having a competent alternator technician modify your alternator for you.

Heavy duty / high output

Alternators can be built in heavy duty configuration, which typically connotes:

- higher current rating

- increased internal cooling (ie, more or better fans)

- ability to make more power in idling scenarios, which is useful for police vehicles, ambulances, and other vehicles that need to idle for long periods of time.

HD alternators for any particular vehicle may be bolt-ins with no modifications required. They do cost somewhat more. The labor cost would remain the same so some people choose to upgrade the alternator when/if the OEM one fails.

Nations and similar alternator builders make alternators for specialty uses.

big three

Note that increasing alternator output may require upgrading stock chassis wiring. Often called “the Big Three”:

- POS from alternator to starter battery

- NEG from starter battery to chassis

- NEG from chassis to engine block

To run a [high output] alternator, ALL of your engine's factory high current cabling will need to be [sized] to support it, including engine and starting battery grounds, and alternator positive. – MechEngrSGH45)

In addition, the wiring from the starter batt or alternator to the house battery bank may require upsizing to actually get that current where you want it to go.

Idle optimized

Some tricks are possible to get higher outputs at lower alternator RPM. Denso uses square windings in some units to pack the windings more tightly.46)

Smaller alternator pulleys may be used to increase alternator RPM at low engine RPM. Caveat: this can overspeed the alternator on higher-rpm engines.

large case

Alternator cases come in two general sizes: large and small. Most vehicles come stock with small case alternators because they are easier to “package” (fit into the available space). Semis, boats, and other vehicles with fewer space limitations may use large case alternators, allowing for more internal cooling, larger or more separated components, ease of repair, higher constant duty outputs, etc.

One is not better than the other; they are meant for different applications.

The mounting bolt pattern may be the same or it may require a different mount. Pulleys, belts, and/or belt lengths may need to be changed.

dual alternators

aftermarket dual setups

In some setups a second alternator is fitted, often externally regulated (see above) and dedicated to charging the house bank. This allows different voltages (24v or 48v) for charging specialty house banks.

If the house bank is Lithium one must plan for sudden BMS disconnect and the effect this would have on an alternator. In a single-alternator scenario the starter battery would provide buffering against load dump.

Balmar 2nd alt kits for Sprinter, Transit, and Promaster can be seen in this brochure (pdf).

OEM dual setups

OEM (factory) dual alternator setups may not behave as one expects. Typically they are controlled separately but both tied to chassis voltage.

Ford

On recent models the dual alts are set up so the primary maxxes out before the secondary kicks in:

In dual generator systems, the PCM keeps the secondary generator in a standby state where it does not generate current unless the primary generator is generating full power and more current is needed to support the vehicle loads. The PCM monitors the output of the primary generator and adjusts the control setpoint of the secondary generator to cause it to provide additional current when needed.47)

This behavior surprised Mortons on the Move, thwarting their alternator-charging plans.

Known configurations:

- 397A = 220A + 157A

- 332A = 175A + 157A

There may be Stationary Elevated Idle Control (SEIC) (“high idle”) available.

RAM

- 380A = 220A + 160A

There is a process to electronically remove the second alternator from the computer by deleting the sales code and that essentially has the truck setup as if it came with just a single one from the factory.48)

GM

Information is limited, but GM factory dual alt setups appear to run the way one would expect in the first place, with load shared between them:

The two alternators are controlled over a common circuit from the ECM so they cannot be controlled independently. The ECM cannot shut one down and let the other one run. It is both or neither.49)

This upfitters guide excerpt contains additional information.

DUVAC

Some older Class A and C RVs came with DUVAC (DUal Voltage Alternator Control)50) setups, which use separate voltage-sensing wires for the house bank.

…the primary reason for DUVAC is to allow the alternator to “compensate” for the voltage loss (turned into heat) in the old generation diode-based battery isolators. There is approximately a .7 VDC loss through the battery isolator. The sense wire/terminal allows voltage on the battery side of the isolator to control the alternator voltage.54)

{As far as I can tell this was a workaround from when many isolators were diode-based so the alternator could not “see” aux battery voltage on the combined circuit55) – secessus} See this TSB. (PDF)

further reading

- Nigel's Too Hot to Handle article

- WorkingOnExploring series on alternator charging

- transient voltages