Table of Contents

DRAFT

Words of Wisdom: “With a few basic design considerations, and an alternator design newer than 25 years old, a direct charging system [for LiFePO4] can be safe, effective, and provide significant benefits. - midwestdrifter1)

Direct charging LiFePO4 banks

There is an often-repeated claim that LiFePO4 house banks will always pull monstrous levels of current and destroy alternators if a plain combiner is used instead of a DC-DC charger. This claim is not supported by either theory or empirical testing. The data below provide actual measurements to help people make informed decisions. We will see that current demand by LFP banks follows a known formula rather than the opinions of people on the internet.

This article will focus on current demand by LiFePO4 house banks. Other objections will be addressed at the bottom.

contraindications

Direct charging is not a good fit for all scenarios. See section below for use cases where other solutions may be required or preferable.

the formula in 60 seconds

This won't hurt a bit.

I=V/R. This means “current2) is equal to the difference in voltage3) divided by resistance4)”.

For us, this means there are two factors that dictate what a battery bank (lithium or otherwise) will demand of the alternator:

- The voltage difference between alternator and battery bank5) – so the lower the battery's voltage the higher the current demanded.

You don't have to fully understand it or get a I=V/R tattoo, but do keep the basic idea in mind as we plunge ahead.

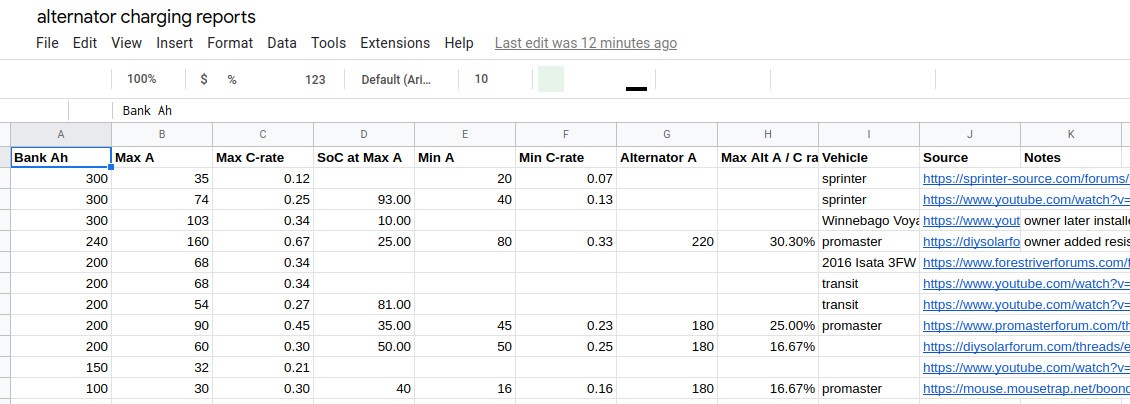

analysis of van-relevant installs

TL;DR: in general we see 0.33C charge acceptance rates at low states of charge, tapering as bank voltage rises. Much like AGM. Across the broad middle of the LFP state of charge acceptance is closer to 0.2C.

This section includes installs that one might find in a typical van:

- banks between 100Ah and 300Ah

- single-alternator systems (no dual-alternator setups)

- standard regulators (no external regulators, internal regulator hacks, etc)

- with rated capacities ≥120A8)

- plain relays, not voltage-boosting DC-DC chargers or voltage-reducing isolators. BiM are included because they are fancy relays.

- NEG return typically through chassis rather than separate NEG wire to battery.

Since it includes screenshots the data will be for installs documented before Sept 15, 2022.

{There is a full list including installs that fall outside the criteria above. It is updated as I find new information – secessus}

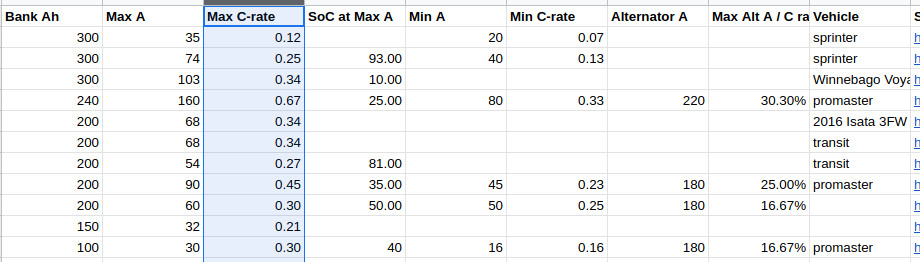

current drawn expressed as C-rate

The first thing to look at is how much maximum current the banks are actually drawing in relation to their C-rate (capacity rating).

Remember the warnings tell us the C-rate will be 1.0, which is the max the BMS will allow under most circumstances.

The average max current drawn from the alternator is 0.33C, or 1/3rd of what the warnings predict. This the same C-rate that AGM pulls when cycled to 50% DoD. It might seem counterintuitive but it is a combination of:

- higher voltage of LiFePO4 compared to lead; and (V in the forumula)

- the resistance introduced by chassis grounding (R in the formula)

There is an outlier that pulls 0.67C at ~10% state of charge.9) That setup has 1awg cables from the starter battery to house battery bank, resulting in extremely low total resistance (9mR). The practical effect of resistance on current will be addressed below, using that owner's experiments for illustration.

why does C appear to decrease as bank size increases?

All other things being equal, current acceptance does increase with larger bank capacities but this increase can be surprisingly small:

IF you have other things in the network with a much higher resistance than the batteries (such as using the frame as a ground return path), changing the resistance of the battery bank [ie, increasing capacity] can have only a small effect. –MechEngrSGH10)

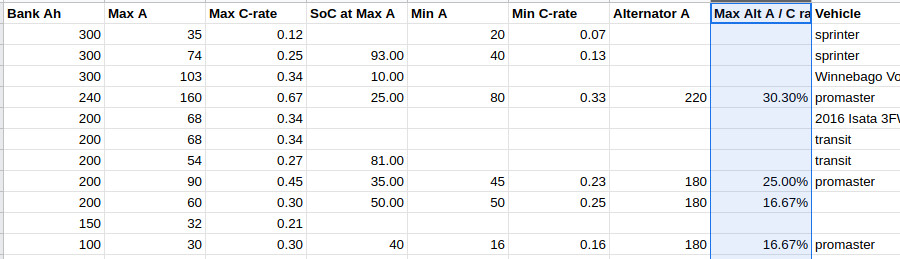

current drawn expressed as percentage of alternator rating

A second way to look at this is how much of an alternator's output the bank draw per 100Ah of capacity:

On average, direct-charging each 100Ah of LFP consumed ~22% of the alternator's rated output.

failures

There are three failures to date, and none comes from the van-relevant section.

Mortons on the Move

500Ah of LFP direct charged with a 225A alternator. This falls outside the van-relevant window since bank size >300Ah.

Mortons on the Move were able to overheat (not damage) the 225A primary alternator with 500Ah pulling 180A on 1/0 cables between the tow vehicle and travel trailer. This setup might have worked with the theoretical ~400A capacity of the dual-alternator system, but the second alt was not cutting in the way they expected due to Ford's implementation; see the 8 minute mark in this video.

They ended up installing a DC-DC charger (30A Orion-TR) to limit current.

Victron video

300Ah of LFP (no BMS) direct charged with a 90A alternator. This falls outside the van-relevant window since alternator rating <120A.

Victron damaged a 90A car alternator with 300A of lithium on a bench (no airflow as when driving). They were able to charge the same bank from a 100A-120A11) externally-regulated Balmar alternator. The Balmar observes alternator temperature and regulates current to maintain alternator-safe conditions.

1977 RV

The 60A alternator in RJS's 1977 RV died after approximately 1 year of direct-charging 200Ah of Lithium at rates up to 41A through a manual switch. He indicates the alt was ≥15 years old at the time.

lessons

- Think twice about direct-charging banks that have 2-3x the capacity of your alternator's rating. If you need to do this use a properly-sized DC-DC charger, external regulation, thermal switches, current reduction with resistance as described elsewhere in this article, etc

- do not idle to charge.

tweaking current with resistance

We don't have a lot of control over alternator voltage (diode-based isolators nothwithstanding) but we can affect resistance.

[with lead chemistries] the battery resistance [is] the large and controlling factor, in the case of LFP, its the wiring and the battery resistance is inconsequential. – MechEngrSGH12) (emphasis added)

NEG return through chassis

using a copper cable ground between the starter and the auxiliary battery is actually part of the overcurrent problem. Using a frame ground tends to add a lot of resistance to the network… – MechEngrSGH13)

Direct-charging setups typically only run the POS wire from the battery14) to the relay; NEG return (aka “ground”) is made from the house bank to the vehicle chassis or frame.15)

Steel has much more resistance than copper:

copper (considered 100%), Aluminum is 71%, Brass is 25%, steel is 12-14% (depending on the alloy), lead (solder) is around 12% and 304 stainless steel (what stainless fasteners are made from) is 2.5%16)

…so a chassis NEG return will increase resistance on that leg by something like 8x. The mass of the chassis material is so great no heating will be observed.

Corollary: it may be possible to tweak overall resistance by trying different NEG return points on the chassis.

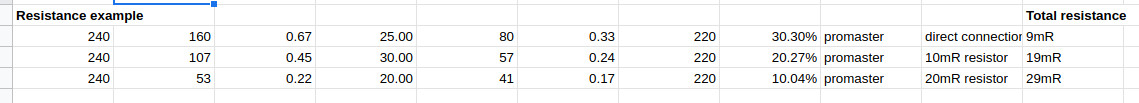

case study

The owner of the van in the higher-current outlier mentioned above had very low resistance in his wiring. He added resistance to see the practical effect on current drawn by the house bank:17)

We can see that adding resistance makes a noticeable difference in the charge current flowing from alternator to bank.

Thinking back to I=V/R, we should not be surprised that tripling R reduced current to 1/3rd of it's unfettered rate. He provided additional datapoints (table to right).

Thinking back to I=V/R, we should not be surprised that tripling R reduced current to 1/3rd of it's unfettered rate. He provided additional datapoints (table to right).

Although he inserted an actual resistor, any component that increases resistance would have a similar effect:

- battery monitor shunts

- fuses

- connecting to positive bus rather than battery POS terminal

- Sizing wire to noncritical spec tends to level out the charging current; high current causes voltage sag, which reduces current.18) For a 14.4v alternator 10% sag means the battery would see 13.0v and at 3% sag it would see 13.97v.

- etc

application

Let's assume battery resting voltage is 13.0 and alternator voltage is 14.0 and circuit resistance is 20mR (.020R).

- I=V/R = (14v-13v)/0.020R = 1v/0.020R = 50A

Let's add 5m Ohm of resistance:

- I=V/R = (14v-13v)/0.025R = 1v/0.025R = 40A

tweaking current with voltage

Anything that reduces the voltage difference (“delta”) between the bank and alternator will reduce current. This delta is the V in I=V/R.

diode-based isolators

Diode-based isolators incur voltage losses, typically around 0.7v.19) This will decrease the difference between battery and apparent alternator voltages, thereby reducing charging current.

It would also reduce final charging voltages, so this might allow vehicles with high chassis voltages like to safely charge LFP. Example: 14.6v → diode-based isolator → 13.9v.

Example: let's assume battery resting voltage is 13.0 and alternator voltage is 14.0 and circuit resistance is 20mR. Diode isolator cause 0.7v loss. We'll do it with a relay first:

- I=V/R = (14v-13v)/0.020mR = 1v/0.020mR = 50A

Let's add the diode isolator20) to reduce apparent alternator voltage:

- I=V/R = (13.3v-13v)/0.020mR = 0.3v/0.020mR = 15A

state of charge

When the bank State of Charge (and therefore voltage) is higher the delta and current will be reduced.

Example: we would expect a bank at 12.5v accept more current than one at 13.5. Using the 14.0v alternator output above,

- I=V/R = (14v-12.5v)/0.020mR = 1.5v/0.020mR = 75A

- I=V/R = (14v-13.5v)/0.020mR = 0.5v/0.020mR = 25A

concurrent charging sources

Even if SoC has not increased meaningfully yet other charging sources can drive up apparent bank voltage, thereby reducing the delta and current. This voltage “surge” during charging is the flipside of voltage sag during discharging.

In practice the most common concurrent charging source for an alternator is solar.

Example: Let's assume the same 14.0v alternator output and solar contribution that pushes up Vbatt by 0.3V

- I=V/R = (14v-13.0v)/0.020mR = 1.0v/0.020mR = 50A without solar

- I=V/R = (14v-13.3v)/0.020mR = 0.7v/0.020mR = 35A with solar

Note: this occurs because alternators are voltage regulated while solar charge controllers can output whatever voltage they want internally as long as voltage setpoints at the terminals are exceeded. So two solar controllers will each contribute their max no matter what the other does until the Absorption setpoint is reached. OTOH, current from the voltage-regulated alternator will decrease as other forms of charging push up Vbank and SoC.21)

current demands of DC-DC chargers vs isolators

For these examples we will assume alternator voltage of 14.4v and circuit resistance of 20mR.

combiner charging current acceptance patterns

Lead batteries have roughly-linear voltage curves. Lithium has a relatively flat curve in the middle 80% and dramatic “knees” at either end (see graph at right). In practice the current acceptance pattern is shaped like the discharge voltage pattern seen to the right.

Lead batteries have roughly-linear voltage curves. Lithium has a relatively flat curve in the middle 80% and dramatic “knees” at either end (see graph at right). In practice the current acceptance pattern is shaped like the discharge voltage pattern seen to the right.

- at very low states of charge (<10% state of charge) voltage will be very low, around 12.0v. This means current demanded will be maximal22) briefly, then quickly level off as voltage comes off the bottom knee. ~120A.

- in the middle 80% voltage will be stable, in the 13.2v - 13.6v range. Charging current will be moderate and stable. 40A-60A, average 50A

- at high states of charge (>90% state of charge) voltage will climb above 14.0v. Current demand will be very low and remaining charging will be slow. This gives ample opportunity to shut off the isolator manually. ≤20A

Word to the wise: if your SoC is ≤20% you may want to allow solar or other charging to bring up voltage a bit before activating alternator charging. At least make sure the vehicle is at cruising speed so the alternator can handle the brief inrush.

DC-DC charging current acceptance patterns

For this section we will assume the DC-DC is sized for the moderate currents seen in the middle 80% above (~50A)

- at very low states of charge current will be limited to the DC-DC's rated output, 50A

- in the middle 80% voltage will roughly be the DC-DC's rated output, 50A

- at high states of charge DC-DC will hold rated output slightly longer then taper faster at the end, 50A, then falling to 0A.

comparison

As long as we stay away from the bottom knee (lowest 10% of SOC) our patterns are largely the same. Only the currents change.

Current levels with DC-DC will remain the same regardless of bank size.23)

Current levels with combiners will vary with bank size, about 0.33C and tapering (see above).

breakeven

Breakeven points (the amount of time it takes for each to replace the same Ah/Wh) are easy to assess with DC-DC since their output is table and difficult with combiners since they taper with bank voltage.

But we can try to estimate how much driving it would take to replace 10Ah in a 200Ah bank (going from 50% to 55% SoC, for example:

- 60A DC-DC - 10 minutes

- 50A DC-DC - 12 minutes

- combiner - ~12 minutes

- 40A DC-DC - 15 minutes

- 30A DC-DC- 20 minutes

- 20A DC-DC - 30 minutes

If the SoC was very low (near cutoff) the combiner would slightly faster, ~7.5 minutes.

reasons NOT to direct charge LFP

- you have a smart alternator or the alternator voltage is otherwise out of charging spec

- you have a small or already-overloaded alternator

- you already own a DC-DC

- your BMS has no low temp charging disconnect and you have no desire to work around that24)

- you want predictable charging rates, like 40A over the next hour. DC-DC will provide this25); isolator charging starts out high and drops as battery voltage rises. You might learn its behavior over time, but it will never be as easy as “40A for 1.5 hours = 60Ah”.

- you want stable charging rates regardless of state of charge26)

- if alternator is your sole charging source. Direct-charging's taper makes it difficult to charge aggressively when the bank is already at high SoC. A large DC-DC or dedicated secondary, externally-regulated alternator might be a better solution for this use case.

- you don't want to think about the battery. DC-DC will either stop charging (Renogy) or drop to float (all others) when charging is complete. Combiners need to be switched off after charging if you are driving long enough to fully charge the bank.

- choosing wiring can require some research

- with DC-DC chargers wire sizing is straightforward: charger output rating + 20% to account for DC-DC conversion overhead

- if isolator wiring is already present from a previous bank, test it while using a monitor or BMS info to watch actual current. You may want to decrease fusing to equal the actual wire rating27) during testing.

- if starting from scratch there is less to go on.

- The most conservative approach would be to size the wiring for 1C (non-critical).

- In the van-relevant examples above LFP banks typically pull 0.33C, or 33A per 100Ah of capacity, so it might be acceptable to size them to 0.5C (noncritical).

- a set of heavy jumper cables and a clamp-on monitor might help assess max current draw before buying any wiring.

assessing your own setup for direct alternator charging

[Note: this section errs on the side of methodical plodding in the spirit of “don't eat this mattress” or “do not juggle chainsaws on the top step of this ladder”. For existing setups it can be as simple as starting the engine briefly to see how much current is drawn and going from there. The existing fuse would intervene if the current is harmfully large.]

assessment phase

- pay attention to the chassis' normal voltage while idling and cruising - this is a benchmark for how the vehicle behaves without aux charging.

- if the isolator is already in use with lead-chemistry banks before the upgrade, pay attention to the voltage and current at which the existing bank is being charged. A a battery monitor or clamp meter will be very helpful here. Specifically we are interested in:

- current acceptance at 50% State of Charge - this will be the highest level of current the battery sees

- voltage when the bank is at 100% State of Charge (likely close to chassis voltage) - this will be the highest voltage the battery sees

- Read and understand your Li battery manufacturer's charging specs - undercharging is fine28); overcharging is less so but is relatively rare in an isolator context.

- Read and understand your alternator's specs. If your vehicle is ok charging a similar-capacity AGM then it will probably be fine with Li. If you want more info:

- measure how much current from the alternator your vehicle requires to run its own loads. Since alternators can, while driving, run continuous current ~1/2 of their rating this means the bank can use (ALTERNATOR RATING / 2) - VEHICLE LOADS. If your bank wants to pull more than that an appropriately-sized DC-DC may be required.

- Read and understand your isolator's specs and functionality

- now make a sanity check about the ability of alternator, your isolator, and your Li battery to cooperate. Refer to the actual reports in the spreadsheet to see if any approximate your setup. If you can measure the total resistance do so and work the formula.

- ensure the fuse between your chassis and battery bank is sized so you cannot draw more than the alternator and wiring can handle

testing phase

[Note: this section might seem like overkill. It is intended to walk first-timers through the process in a methodical way. Experienced DIYers will already have internalized this kind of process.]

For measuring charging current you can use the battery's BMS, battery monitor, or clamp meter. If your vehicle has gauges for RPM and voltage you can use those. If not, you might pick up an inexpensive bluetooth OBDii dongle like this to see the values.

- look over the sanity checks in the Assessment section above

- make the first test run a brief one and with the Li well-charged.29)

- begin with the relay disabled

- start the engine and let it idle for a minute. Observe both the engine RPM and the chassis voltage; this is your baseline for how the vehicle acts when not charging the house bank. Charging current from the alternator to house bank should be zero.

- enable the relay. Observe the engine RPM, chassis voltage, and charging current

- If either the RPM or chassis voltage drops and stays there30) then the alternator is overloaded at idle.

- increase RPM slightly (2000rpm?) and hold it. Observe chassis voltage and charging current.

- If either value rises and stays higher this suggests the alternator may be able to handle the load only while driving.31).

- hold the RPM and disable the relay. Charging current from the alternator should drop to zero.

- If the chassis voltage stays stable then the alternator can handle this level of current at this RPM.

- If chassis voltage rises and stays there this would suggest the alternator is overloaded no matter the engine/alternator RPM and direct charging is not recommended.

- Turn off the engine.

- if solar or other charging source is present, disconnect those chargers and repeat #1.32)

- repeat steps above with the Li bank at lower and lower states of charge, down to the lowest state of charge you expect to recharge from alternator.

Note: this same process also works for testing the size of a DC-DC charger. The difference is SoC doesn't matter since DC-DC output will remain stable for the most part regardless of SoC. If the DC-DC can be derated we would adjust the output current until the alternator was happy at idle (or at higher RPM, whichever suits your use case).

caveats

- Only alternator charge while driving (no idling except for brief preliminary test).

- Pay attention while charging from alternator to keep from overcharging the Li or holding for long periods at high states of charge. You may want a manual disconnect or HVD to shut off alternator charging due to excess voltage or if the bank is already charged. These can be added on the D+ wire (ignition triggered) or electronics ground wire (VSR, solenoid, or voltage-triggered DC-DC)

- if current is excessive but you want to direct-charge, you can tweak acceptance with resistance or voltage as seen elsewhere in this article

the parts list

After you have completed the assessment above here are the required parts:

- continuous duty relay,

- a good solenoid like Cole-Hersee or similar. $30

- or VSR like Battery Doctor, $65

- or diode/FET-based isolator if one wants to reduce current further, $7033)

- toggle switch to deactivate relay at will, $5

- optional: high voltage disconnect to automagically disable the isolator at 14.0v-14.2c (whatever your desired charging setpoint is), $15. You can do this with the manual switch above if you are diligent. Also not needed if the alternator's native voltage is <14.2v or so

objections

No one is insisting you must to direct-charge your LFP or claiming it is a good fit for all use cases. This article intends to show direct-charging is practical and effective in more use cases than people think.

Let's address some other common objections.

the alternator cannot fully charge LFP

Yes, it can. LFP will charge to ~100% SoC quite smartly at ≥13.8v. Does your alternator put out ≥13.8v? LFP will actually charge to ~100% SoC at voltages as low as 13.6v (3.4Vpc), it just takes longer than most of us drive in one stretch.

Which brings us to the next point: LFP does not need to be fully charged the way lead does. Get as much charge as you need and stop if you want. Or keep going.

BMS disconnect will damage the alternator

- why are you overcharging your bank so badly that the BMS is shutting down to keep you from damaging it?

- the starter battery is in the circuit and can absorb the transients. What do you think happens when you shut off the headlights, or heater blower, or those heated seats?

you will overcharge your battery

If you are driving long enough to reach the desired state of charge (80%, 100%, whatever), you can disable alternator charging if desired.

addendum: advantages of direct charging

Cost. If you already own a combiner then it's already paid for. If you are installing one new it would be much cheaper for the average current than DC-DC.

Direct charging tapers during Bulk and DC-DC does not. In effect the combiner provides the most current when you need it most (batteries are low) and the least when you need it least (batteries nearly charged). This happens because when the batteries are more charged there is a smaller difference (“delta”) between the alternator output and bank resting voltage (I=V/R again). There are some related effects:

- direct charging backs off when other charging sources are present. This happens because the other charging sources affect the “resting” voltage of the bank and so the voltage delta. This can help prevent excessive charge rates. Example: 100Ah battery, 30A DC-DC and 30A solar. If both systems were running full blast the combined charging would be 60A, or 0.6C. That is above the recommend charging current (0.5C) of most drop-ins. A combiner in the same situation might34) drop to 15A contribution for a total of 45A. That would be 0.45C. Of course if you want to hammer at full speed all the time then DC-DC is better for that.

- direct charging backs off at higher states of charge35). Cell manufacturer datasheets typically derate charging limits when the battery is >80% SoC. Engineering Explained has a relatively-accessible video that explains how SoC and charge rate affect LiFePO4 degradation.

addendum: other charging reports

This info has been moved to the Other Reports tab on the main spreadsheet It includes setups that lack incomplete info, or interesting related setups.