Table of Contents

Tweaking a PWM controller for maximum power

PWM controllers are inexpensive and durable. Their chief downside is their ability to generate power is limited when battery voltage is low (MPPT output is unaffected by battery voltage). This page is intended to help people get the most out of their PWM system. It assumes the 'dweller owns a configurable PWM controller.

Note: much of this information also applies to tweaking shunt controllers.

PWM's achilles heel

During charging with a PWM controller the solar panel will be running at the voltage of the battery bank.1) Unfortunately, this is almost never the voltage at which the panel makes its rated power (Vmp). The panel will make less and less power when battery voltage is low.

This affects charging in all three charging stages but it is devastating in Bulk. Let's do some math to see why.2)

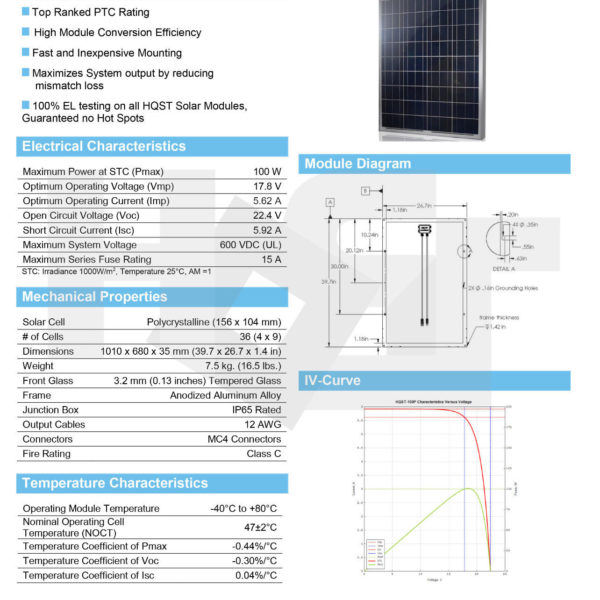

Consider the spec sheet for a random 100w panel (right). 100W is made when the panel is run at 17.8v (Vmp). We will use Imp for our math, but the absolute numbers are not important, only the pattern. Current will usually be less under normal conditions, but can spike to Isc under some conditions.

Consider the spec sheet for a random 100w panel (right). 100W is made when the panel is run at 17.8v (Vmp). We will use Imp for our math, but the absolute numbers are not important, only the pattern. Current will usually be less under normal conditions, but can spike to Isc under some conditions.

17.8v x 5.6A = 100w ←- rating under laboratory conditions3)

17.8v x 5.6A = 94.70w ←- MPPT running at 95% efficiency

PWM harvest

14.8v x 5.6A = 82.88w ←- power at a high Absorption voltage, as with flooded lead acid

14.4v x 5.6A = 80.64w ←- power at a lower Absorption voltage

14.2v x 5.6A = 79.52w ←- power at a low Absorption voltage

13.8v x 5.6A = 77.28W ←- power at high Float, as with deeply cycled banks

13.2v x 5.6A = 73.92W ←- power at low Float, as with lightly cycled banks

12.7v x 5.6A = 70.61W ←- power at 100% state of charge (SoC)

12.4v x 5.6A = 69.44W ←- power at 75% state of charge; bulk charging

12.1v x 5.6A = 67.76W ←- power at 50% state of charge; bulk charging

10.0v x 5.6A = 56.00W ←- battery bank accidentally run flat

This last number shows how far off PWM output can fall when battery voltage (Vbatt) is at its lowest.4) It's also when the battery needs the most current to get out of that deep cycle trough.

the plan

Here are steps to take to maximize power from the PWM controller, in order from greatest effect to least effect.

delay loads until after Bulk

During the bulk charging stage the battery needs every bit of power it can get. Any loads applied during this stage slow down charging and, more importantly, prevent the system from reaching power-making voltages as soon as possible.

Wait until your bank is well into Absorption before using discretionary loads.

set Vabs and Vfloat relatively high

Since the panels make more power at higher voltages5) cranking up Vabs and Vfloat to higher-but-still-sane levels will result in more power being harvested.

Using the above panel as an example, Vabs of 14.7v will yield 3.5% more power than a Vabs of 14.1v. Vfloat of 13.8v will yield 4.5% more power than a Vfloat of 13.2v.

Note: consult the battery manufacturer's recommendations for the actual maximum voltages. Controller presets often are set too low by the factory since they don't know what battery you will use it with. Better safe than sorry, say their lawyers.

DO invest in the $10 temperature probe option.

battery: maintain a higher state of charge

This may seem obvious, but remember:

- since state of charge is correlated with voltage; and

- voltage is correlated with panel output; then

- keeping your bank as charged as possible will let the panels produce the most power for conditions

In other words, the lower your battery voltage gets the worse the pwm charging works. There are two courses of action to take that will help reduce this effect.

- Cycle less deeply - Instead of cycling to 50% state of charge (12.2v) consider cycling to only 75% SoC (12.4v).

- combine your solar charging with even small amounts of alternator or shore power charging. Either one of these will help get the bank “out of the mud”, particularly if they are added early in the morning. An isolator generally costs less than upgrading to mppt.