User Tools

This is an old revision of the document!

Table of Contents

Words of Wisdom: “With a isolator you would run the truck early to get a fair amount of the bulk charging done and let the solar finish it off the rest of the day.” – jimindenver1)

The bottom line is that current simply flows where it is needed, batteries will take what they need when batteries are combined, and the voltage becomes equal among the new combined bank. Unless your charger, alternator or solar/wind system is pumping out an incorrect voltage for you bank you will not over charge using an ACR. mainesail2)

Alternator charging

aka Split Charging for our European friends

In a dual-battery system3) some of the alternator output is used to charge the house batteries when the engine is running. When the engine is not running the house battery is electrically isolated from the starter battery to keep from draining it and leaving you stranded. So the devices that handle the isolating/combining duties are called battery isolators. There are several different types.

Normally only the POS4) wire is used to route power with an isolator; the NEG side is the chassis ground. If no chassis ground is available a NEG wire will need to be run also.

when alternator charging works well

- when batteries are deeply discharged

- when combined with solar or some other higher-voltage charging source

- when used with battery chemistries like lithium that do not need staged charging.

- when used with a battery-to-battery boosting charger that can produce correct charging voltage

limitations

Alternator charging is generally only practical for the bulk charge stage due to relatively low voltage output and the long time periods required for absorption.5) It is unlikely to get lead-chemistry batteries fully charged unless one is driving for several hours. Failure to fully charge lead batts regularly6) will impact battery longevity. If one drives often a combination of the alternator doing bulk charging and a small solar doing the rest is good match.

Vehicles with smart (variable voltage) alternators may not be suitable for charging with normal isolators.7) See below.

See Is Solar Mandatory? for ideas on how to charge primarily by alternator.

effect on alternator

Charging the house batteries from the alternator increases the load on the alternator and can be expected to contribute to somewhat earlier failure. In practice it's usually a non-issue if one avoids overheating8) or overloading9) the alternator.

If/when the OEM alternator does fail10) a higher output one can be installed for not much more than it would cost to replace the original.

SternWake reports idling while charging causes a sharp increase in alternator temperature.11) To avoid this, do your alternator charging while driving so airflow over the hot alternator will help cool it.

effect on GDI engines

High-performing engines with Gasoline Direct Injection can experience carbon fouling on the backside of intake valves, which can cause “drivability woes… misfires” and dislodged carbon flakes can cause “turbocharger issues… catalytic converter damage.”12)

Anecdotally the problem appears to be worsened with excessive idling, although this may be a subset of situations where “the engine doesn’t run long enough or hard enough to get hot enough to burn any of the carbon off.”13)

smart alternators

Traditional alternators typically try to hold a set voltage. Smart alternators talk to the vehicle's ECU (compuuter) and can vary output voltage wildly depending on present conditions. It might unload the alternator during heavy acceleration to reduce parasitic losses, or run the alternator at high voltage just after starting to speed up the recovery of used energy.14)

The use of plain isolators with smart alternators may result in the rapid cycling of the isolator's circuit (with voltage sensing types) or the discharge of the house battery into the starter battery (solenoid type).

DC-DC chargers and/or isolators with an awareness of smart alternators may be required.

Furher reading: Redarc - standard vs smart alternators

isolators

Power from the alternator is shared with the house battery using an isolator (“Split charge relay” / SCR) of some sort. This allows the house battery to charge but does not allow the house battery to pull power from the starter battery.

constant-duty solenoid

A constant-duty solenoid is an electromechanical device which uses an electromagnet to complete the charging circuit when the engine is running. Solenoids are generally cylindrical. Energizing the solenoid will cause a 0.5A - 1A current drop between the alternator and house battery. Exception:

Latching isolators use latches15) instead of electromagnets to hold the circuit closed, eliminating that vector of power consumption.

A constant-duty solenoid is an electromechanical device which uses an electromagnet to complete the charging circuit when the engine is running. Solenoids are generally cylindrical. Energizing the solenoid will cause a 0.5A - 1A current drop between the alternator and house battery. Exception:

Latching isolators use latches15) instead of electromagnets to hold the circuit closed, eliminating that vector of power consumption.

16). SternWake recommends the Blue Sea 901217) although non-marine units in the $20-$50 range are more common in vans.

Solenoids can be used for self-jumpstarting if the chassis battery has enough juice to engage the solenoid.

voltage-sensing relays

voltage sensing relays (VSR, also called Automatic Charging Relays or ACR) are solenoids with a bit of extra logic to know when to connect/disconnect. The VSR does not get trigger voltage from the fuse panel but rather reads the voltages of one18) or both19) batteries to know when to switch on.

voltage sensing relays (VSR, also called Automatic Charging Relays or ACR) are solenoids with a bit of extra logic to know when to connect/disconnect. The VSR does not get trigger voltage from the fuse panel but rather reads the voltages of one18) or both19) batteries to know when to switch on.

This kind of isolator may have a “combine” override function to enable self-jumpstarting.

in its simplest form, all an ACR really does is parallel batteries when charging is present and un-parallel batteries when there is no charging present. It does this automatically with no human forgetfulness.20)

- single voltage sensing - this type reads the voltage of only one battery. In the case of an RV it would read the voltage of the starting battery. When it is high enough above resting voltage (ie, being charged by alternator) it connects the starting and house batteries.

[secessus says: “IMO the practical benefit (if any) to charging the starter battery “first” is keeping the load on the alternator reasonable. In practice, the isolator generally connects the two within a few seconds.”]

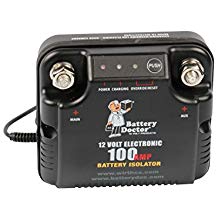

Examples: Sure Power 1314, BlueSea BatteryLink, Battery Doctor, Victgron CT. - dual voltage sensing - this type reads the voltage from both sides and when either is high enough it connects the batteries. This may or may not be what an RVer wants

Examples: Sure Power 1315, BlueSea SI-ACR, JayCorp Smart Dual Battery 140A Isolator21), Precision Circuits BIM22) - DC-DC isolators (aka b2b isolators) that boost alternator voltage to more appropriate levels for lead chemistries and can do multistage charging. These have their own page.

Note: voltages-sensing (with or without delay) can be added to plain solenoids.

solid state isolator: diode-based

Note: this type of isolator is no longer common for our uses.

These isolators are electronic devices which use diodes to prevent depletion of the starter battery. Isolators are generally brick-shaped. Diode-based isolators have a 0.5v - 1v drop between the alternator and house battery. This may be desirable if the house battery is a wants lower-voltage charging like LiFePO4.

Examples: Victron Argo-diode, Cole-Hersee 48122

Notes:

- solid state relays can't combine batteries for self-jumpstarting

- the unidirectional nature of the diode isolator may be desirable to prevent “backflow” of higher voltage from the house bank to the chassis.

- diode-based isolators are typically installed between the alternator and starter battery. This is in contrast to solenoids and VSRs which can be daisy-chained off the starter battery. The batteries are, in effect, always isolated and never electrically combined.

- Some 1-wire “self-exciting” alternators require a diode isolator with an Alternator energize feature.23)

- some diode-based isolators (Victron, see above) have a feature to slightly tweak alternator voltage upwards to compensate for voltage drop across the isolator

solid state isolator: FET-based

This type of isolator is similar to the diode-based one above, except that FET components are used instead of diodes, minimizing voltage drop. They tend to cost 2x as much as the diode versions.

manual switch

The simplest and least-featured isolator is a manual switch.

The simplest and least-featured isolator is a manual switch.

A manual battery switch normally has 4 positions: A, B, A+B, and Off. A would be for the starter battery and used during starting. B would be used for house use when one is not driving. A+B could be used to combine both sets for starting or for charging while driving. This kind of setup is prone to user error. A manual switch has no current or voltage losses.

lithium-specific

The Precision Circuits Li-BIM is a lithium-specific isolator with some differences:

The Precision Circuits Li-BIM is a lithium-specific isolator with some differences:

- the VSR circuit disconnects at 13.4v when there is no charging occuring on the alternator side. This eliminates the “gotcha” of the circuit staying closed due to high Vbatt.

- the isolator opens the circuit (disconnects) regularly to allow alternator cooling. Charge for 15 minutes, disconnect for 20 minutes, repeat.

- the isolator disconnects when it detects >= 14.4v on the alternator side, to avoid overcharging

The unit supports self-jumpstarting but a switch must be installed by the user. 160A and 225A models are available. BB suggests the BIM is recommended for lithium banks >= 300Ah.24)

misc

[note from secessus: “not sure what's inside these solid state isolators”]

The Magnum Energy ME-SBC is notable for some unusual features:

The Magnum Energy ME-SBC is notable for some unusual features:

- configurable connect/disconnect setpoints

- ability to drive a solenoid, which allows for much greater current

Xantrex makes a 15A Digital-Echo Charge isolator.

The Mastervolt Charge Mate Pro 90 is an electronic current-limiting isolator.

sizing an isolator

If an isolator is oversized it will cost more for no benefit and will self-consume somewhat more energy to hold the combining circuit closed.25)

If an isolator is undersized (less common) it will not be able to carry enough current, resulting in overheating and/or sudden shutdown.

Most AGM will pull about C/3 (33A for a 100Ah bank) but premium brands may do more. Flooded lead-acid batteries tend to pull less current (C/5, 20A per 100Ah of bank). If your flooded back will only pull ~40A, or your AGM bank 70A then there is little reason to spend more money on a 150-200A isolator.

Lithium in particular has low internal resistance and can pull 1C (100A for an 100Ah bank) or more. Victron posted a video showing it is possible to “smoke” an alternator while charging lithium. Since lithium does not care much about state of charge, there is little reason to go for maximum force lithium charging. Some Li bank owners use DC-DC isolators which limit themselves to a particular output (20A, 60A, 100A, etc).26)

Reasonable charging rates can also be easier on the alternator when charging suddenly stops, whether by completion27) or BMS intervention. Blue Sea makes an alternator field disconnect which shuts down alternator power just before disconnecting the load, but this may be chiefly applicable to marine alternators. Others have discussed installing a small lead-acid battery parallel to the Li bank; in theory this could soften the blow from Li leaving the circuit. Other sources suggest the presence of the starter battery would be sufficient.28)

flooded lead-acid

FLA batteries can accept up to C/5 in Bulk stage.

Example: a 200Ah FLA battery bank will pull up to 40A29) in Bulk charging. An isolator rated for constant duty at 40A30) would be sufficient.31)

AGM lead-acid

Consumer-grade AGM batteries typically will accept C/5 - C/3.

Example: a 200Ah AGM bank will pull up to 67A in Bulk. A 75A isolator32) would be sufficient.

Note: high-end AGM like Lifeline, Odyssey, Rolls, etc, can pull massive current when charging. 200A+ would be possible for the example bank and could shorten the life of a stock alternator.

lithium

Lithium also has the ability to accept massive amounts of charging. It will do so across the entire charging range, as lithium does not have an Absorption phase the way lead-acid does.

Example: 200Ah of lithium could easily accept 200Ah+. There are mitigating factors, however.

- Because lithium can use about 80% of it's capacity instead of 50% for lead-acid, 120Ah of lithium is a common replacement for 200Ah lead-acid banks. So the lithium bank would “only” draw 120A instead of 200A.

- drop-in lithium banks like Battleborn have a battery monitoring system (bms) to shut down charging if current exceeds specs.

sudden disconnection

Sudden disconnection of a large load33) when the alternator is running can damage the alternator and any operating chassis electronics. Sudden disconnection can occur when:

- an isolator shuts off due to current beyond it's rating

- a BMS shuts off lithium charging. This can include overvoltage, overcurrent, temperature extremes, etc.

The existence of the starter battery should attenuate the problem but keep the issue in mind.

gotchas

These side effects are usually unimportant and the average user will likely not notice them. They are listed here for completeness.

- Solar charging while the isolator circuit is closed (ie, batteries connected) can pass higher-than-normal voltage to the chassis and starter battery. Workaround: see notes on HVD and DC-DC charging below.

- Voltage-sensing relays can be unintentionally triggered34) or “held closed”35) by voltage from the solar-charged side in some scenarios. Workaround: address with HVD as below if desired, or with a DC-DC charger triggered by ignition rather than by chassis voltage, or by putting a switch on the trigger wire.

- Idling the engine to charge house batteries can overheat the alternator,particularly older-style ones that do not reduce output to control high temps. Workaround: Don't plan to idle to charge from alternator. If you do, a fan may help cool the alternator.

- In early morning when house battery voltage is lowest, a plain solenoid may unintentionally allow depleted batteries to pull down the starter battery. Workarounds: use a VSR, or start the vehicle immediately after inserting the key36).

- Solar charging while the engine is running may get "stuck" at alternator voltage. Workaround: higher solar wattage, DC-DC charger, or a switch to disconnect isolator after alternator voltage is reached. The Victron Cyrix-ct isolator could be useful here, as it appears to disconnect >13.8v.37)

- Alternator charging may bring some battery chemistries (like bare lithium cells with no BMS) to unsuitably high voltages. Workarounds: A high voltage disconnect can restrict alternator charging to lower voltages. DC-DC chargers can also regulate voltage provided to the house battery.

wiring

2 gauge copper wire connecting the coach and house is recommended for most alternator charging installs. SternWake recommends attaching at the alternator rather than the battery.38)

Note that you will only have to run the POS+ leg of wire to the house battery as the chassis ground is usually the other leg.

alternator hacks

There are ways to get the alternator to pump out more power:

- a higher-output alternator will put out more power

- a different voltage regulator for older vehicles, as demonstrated by SternWake, increases the voltage available for charging but also increases the coach voltage.

- a Sterling “fake load” regulator will cause the alternator to put out more amps and then will DC-DC convert the voltage up to correct charging range.39). This is the opposite direction of how MPPT charging works. Also see b2b chargers.

using the coach battery only

A simple possible approach would be to replace the starter battery with a marine or AGM battery.40)

charging trailer batteries

Some amount of power can be passed along the 7pin harness, usually enough to maintain the trailer's battery and run small loads. For the purposes of this discussion the important wires in the 7-pin are:

- battery hot lead, typically black.

- ground41) wire, typically white.

The minimum size for these wires is 12ga and some heavier models use 8ga.

current on different sized wires

Given: a 3% maximum voltage drop42) and a 40' round-trip wiring run from alternator to trailer battery we can provide Float voltage to the trailer battery at these rates:

- 12ga ~5A

- 10ga ~8A

- 8ga ~10A

workaround: voltage boosting

More power (and more appropriate charging voltages) can be passed along the 7-pin by injecting higher voltages into the harness.

The basic idea is alternator → DC boost to 36v or something → run down the 7pin charging wire to the trailer → MPPT charge controller → battery

Using 12ga wire as an example, 5A @ 13.6v = 68w. After the same 3% voltage drop and MPPT conversion losses the boosted setup would deliver 166w, and be able to “smart charge” the trailer battery at appropriate voltage.

further reading

- Split Charging Guide - a British page. Note the following differences in terminology from American English:

- “split charging” == alternator charging

- “leisure battery” == house battery